Research and publications

TOXIC GASES IN THE SMOKES

Toxic gas effects assessment - Transfeu Project

TRANSFEU HAS ACHIEVED ITS FIRST OBJECTIVE

Analisi del progetto TRANSFEU

RESEARCH PROGRAMMES

April 2009 – November 2012

The following results have been achieved:

- A new repeatable and reproducible fire test method for the measurement of toxic gases has been developed (67 products have been tested according to this test method). It is based on a continuous analysis of gas versus time with FTIR (Fourier Transform Infrared Spectrometry)

- A new pragmatic conventional classification system for the toxicity of effluents released by products on trains has been proposed.

This classification is based on the time to reach an incapacitation of passengers and staff. It has been validated by comparison with the full-scale test in the carriage.

- A general description of the fire safety engineering methodology used for surface transport has been written by TRANSFEU.

- It describes the fire safety objective, the fire risk analysis approach, the design fire scenarios and safety criteria, the numerical simulation tools and what data should be used.

- Numerical tools and the simulation method have been developed to simulate the fire effect on the structural integrity of fire barriers, the evacuation of people, the growth of fire, and toxic effects on personnel and passengers due to the combustion of products.

These simulations have been validated by comparing the results with full and actual scale tests.

ROLAND

ROLAND is a program that L.S.F. has coordinated under contract with the EU Commission and with European associations and industries of the building sector..

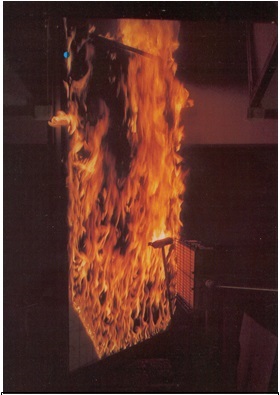

This is the development of a semi-scale method conceived by L.S.F., which, under the conditions of the established thermal attack – 40 kW/m2 – allows to measure with good precision, repeatability and reproducibility, the starting time, the propagation of the fire on the surface in different directions, the amount of heat produced by combustion (by means of the flue-gas temperature curve) and the opacity of the smokes emitted.

It is considered a “simplified” semi-scale method due to the very low cost of both equipment and testing. It also showed a good correlation, it would be more correct to say correspondence, with the data obtained with the Room Corner Test (full-scale test – reference scenario).

Description of the main NON-CONFIDENTIAL research carried out

Conclusions on the differences between real-scale and small-scale test results

Electrical cables are a very particular product that, as far as fire behaviour is concerned, deserves a separate discussion.

The complete assessment includes ignitability, that is the ease of ignition when subjected to a relatively weak thermal attack such as a flame of relative power or a few kW/m2 radiation, the propagation and the quantities produced, over time, of heat, of opaque smokes and toxic gases. Each of these phenomena, which in jargon we call parameters, contributes to calculate a hazard assessment that then determines the “class”, used in fire safety regulations, to correlate fire performance with the criteria of use in various scenarios. The cable has some peculiarities: it is a composite product, sometimes with many components, that present themselves to the stresses of the fire in successive phases, determining its trend. That varies during the development of the fire itself according to the components that are gradually affected. The outer sheath, the fillers when present, the sheaths of the various internal cables, the nature of the cables and the diameter of the various components. The composition of the conductors, diameter shape and total weight also affect the behaviour of the cable.

We have worked hard and for several years, since 1998.

The documents that we present to you are only related to some research , submitted to ISO TC92sc1 and sc3, to CEN, to the Commission of Brussels that financed it in part. Other jobs such as: the efficiency of the optical cable during prolonged fire, to check the functioning of the signaling and transmission system in the tunnel, for example, which is owned by the industry that made it run: at that time I was fascinated by a device able to slice the optical fibre, measure the accuracy of the cut at 90째 (a small difference was reported, so as to correct the error of even just one or two degrees, which would compromise the signal) and then perform the welding. It cost, at that time, about 65 million lire: the operator kept it with an almost morbid attention. It was also used in transoceanic cable-laying ships, and there were very few examples in circulation. The main conclusions that we can consider today acquired in this area are the following:

- Both the equipment and the procedure for simultaneously measuring propagation (which has always been foreseen), heat release, opaque smoke emissions and toxic gases have been improved. In a single real scale test, therefore very reliable as very realistic. In the construction sector, the toxicity of effluents is not yet taken into account in the regulations, while it is in the transport sector, especially in the railway and maritime sector

- bench scale tests, have a relative significance; the gases we find in storage equipment, such as the ISO 5659-2 chamber, are NOT the same as those detected in full scale tests”in the first we always, or almost, find formaldehyde, which we no longer find in full scale tests, where there are always flames. Also tests involving the analysis of one gram of combustible product for each of the components present in the coatings and fillers, by bubbling the gases in the water bottles, They DO NOT give enough information to predict the release of the cocktail of toxic gases species of the cable in its entirety.

- In addition, today we use the FTIR, whose acquisitions (which do not disappear in the sink drain as the solutions for wet chemistry analysis) enter the computer to future memory and control: interferograms can be “reread” years later, discovering species for which, at the time, the calibrations could not be made. Discovering carbonyl fluoride in 2006 from a product tested in 1994 is a great satisfaction, for example, and only the FTIR allows this type of verification.

The small-scale method using the ISO 5659-2 camera with the application of the FTIR, thanks to the TRANSFEU program, has reached a level of reliability never before achieved in terms of repeatability and reproducibility. (For information on the changes that led to this result, please refer to the relevant chapter of TRANSFEU). Recently, we have compared the results of small scale with those of real scale, and we have found that at 50kw/m2 of irradiation the first system always produces formaldehyde, while this gas, rather dangerous, is not found in the real scale tubes, though the heat attack is more or less equivalent. The cause is both ventilation, controlled but present in large-scale tests while absent in the ISO chamber, accumulation, and in the presence of flames in contact with the cables in the first case while in the second the decomposition is caused only by the radiation of the radiant cone. At ISO we were until recently convinced that the pilot flame was not necessary to obtain combustion and therefore in the test at 50 kW/m2 the pilot flame is not provided.

We must admit the error: the same tests repeated with the pilot flame produce different FEC values because formaldehyde never appears.

It will be possible in the future to add the pilot flame also in the tests at 50 kW/m2, but I remain convinced that the full-scale tests are more representative of the real fire and therefore more reliable to evaluate the behaviour of the products, and also represent a significant cost reduction.

BELFAGOR

It represents a pre-normative European research program initiated by the European Commission DG XII (General Directorate Research and Scientific Development) and DG III (General Derectorate for Industry) managed in Cooperation with the following Institutes:

- AIDIMA – Spain

- BAYER AG – Germany

- CENTEXBEL – Belgium

- LNE – France

- LSF – Italy

- RAPRA – United Kingdom

- TNO – The Netherlands

- IKEA – Denmark

The program was coordinated by LSFire Laboratories. The objective of the BELFAGOR program is to provide technical and scientific support for the functional needs provided in the First Essential Requirement of the draft proposal Directive on fire behaviour of Upholstered Furniture, concerning the articles and components that reads: “First Essential Requirement: initial ignition level. The upholstered furniture and related articles should be designed and manufactured so as not to ignite on the exposure of different types of heat source classified in three levels of risk (domestic, public places, prisons and psychiatric hospitals).

“Jim Quintiere, professor at MARYLAND UNIVERSITY, asked me the availability to collaborate on the research that his best student would have to do for his thesis in fire engineering, funded in part by NIST in Washington. Jim knew about our room corner, and the first research we did for the ISO. Until then, the thermal attack and the mechanism to reach the flash over had been studied a bit roughly, and the measurements presented by Matti Kokkala of VTT had been performed in an open dihedral, as is also shown in the text. I joined the proposal, Scott stayed with us a few weeks, he brought a nice equipment for data acquisition, we built together the plates that would work as radiometers etc. His degree was a success, I was invited to the presentation of the document to NIST, which published it among its research: it was an important step for us too for the use and knowledge of the ISO 9705 room corner test, which was adopted as a reference scenario, at least in theory, by the CEN classification system.”

During some tests of full scale (houses built with sandwich panels of different nature), we wanted to monitor the progress of opaque smokes inside the building. Some of the optical groups used at Voghera have been mounted in order to measure the time in which visibility is cancelled at different heights before reaching flash over and/or before exiting the top of the door.